VXB

CNC Manual Slide Stage Linear Stage Actuator 500mm Ballscrew 1605 Optical Axis Linear Rail Guide C7 - Ruler for CNC Router Controller X-Axis Stage

CNC Manual Slide Stage Linear Stage Actuator 500mm Ballscrew 1605 Optical Axis Linear Rail Guide C7 - Ruler for CNC Router Controller X-Axis Stage

Couldn't load pickup availability

500mm Manual Linear Slide Table with Handwheel

✔️ SFU1605 Ball Screw - C7 Precision - 20" Travel Stroke

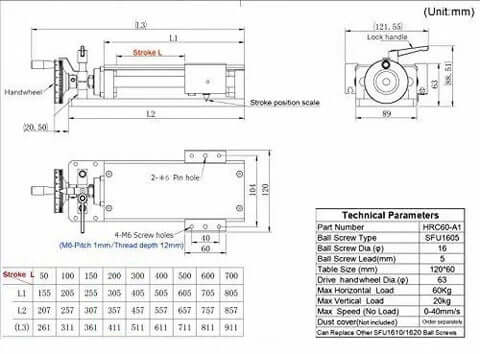

This 500mm (20") manual linear actuator is built for high-accuracy positioning and smooth motion in CNC and automation systems. It features an SFU1605 C7-grade ball screw for ±0.02mm repeatability, a laser-engraved handwheel with a locking pointer, and dual optical-axis guidance. With a rust-resistant 6061 aluminum frame and CNC-machined precision mounting points, it's ready for X, Y, or Z-axis applications.

📦 Shipping Note: This item will be shipped within 10 to 14 days.

✅ Stroke Length: 500mm (20")

✅ Ball Screw Type: SFU1605 (16mm diameter / 5mm lead)

✅ Accuracy: C7 grade (±0.02mm)

✅ Repeatability: ±0.02mm

✅ Work Plate Size: 120mm (W) x 60mm (H)

✅ Guide Rails: Double optical-axis linear system

✅ Material: 6061 aviation-grade aluminum, sandblasted and rustproof

✅ Mounting: CNC-processed precision hole layout

✅ Handwheel: 360° laser-engraved with pointer and lock

✅ Ruler: Side-mounted HD ruler for precise manual reference

✅ Compatible with: Stepper motors, servo motors, AC/DC motors (sold separately)

✅ Use: Suitable for direct X/Y/Z-axis setup in CNC and automation

| Stroke (mm) | Horizontal Load (max) | Vertical Load (max) | Weight (kg) |

|---|---|---|---|

| 100 | 50 | 25 | 4 |

| 200 | 40 | 20 | 4 |

| 300 | 30 | 20 | 4.6 |

| 400 | 30 | 20 | 5 |

| 400 | 30 | 15 | 6 |

| 400 | 30 | 15 | 6.5 |

💡 Why choose a 500mm manual linear actuator with ball screw?

A 500mm stroke offers extended travel while maintaining high accuracy and rigidity - perfect for long-range CNC operations, camera sliders, automation arms, or inspection tables.

A robust, motor-upgradable solution built for performance and precision in custom motion systems.

Share